Rotational Moulding: The Process and Advantages

14-12-2023

Rotational Molding

Rotational molding, also known as rotomolding, is a specialized technology distinguished by its production of small batches and large, hollow bodies. It relies on the adhesion of plastic materials to rotating hollow molds.

This process is widely used worldwide and has experienced significant growth, especially appreciated by designers seeking high qualitand flawless finishes.

Since 1978, we at Italveneta Didattica have adopted this molding technique for the production of large outdoor and indoor games: our CUBIC TOY.

Let's explore more about this technique together.

How does rotational molding work?

The phases of the rotational molding process include loading the mold with polymeric material, heating the mold in an oven, and rotating it to allow the material to adhere to the mold walls, taking the desired shape.

At this point, it is crucial to carefully manage the heating and rotation times to achieve optimal results.

Subsequently, the mold is cooled while still rotating, allowing the polymer to solidify into the required shape.

Once the material has sufficiently hardened, the mold is opened, and the obtained piece is extracted.

Advantages of rotational molding

Rotational molding offers several advantages over other polymer processing technologies such as injection molding, blow molding, and thermoforming.

These include the simplicity and functionality of the process, the elimination of the need for finishing operations, reduced waste production, and flexibility in producing small batches.

The market for rotational molding machines for plastic materials is considered a niche market but has recorded an average annual growth of 3.4% in the last decade, reaching a global value of $825 million in 2019.

In terms of polymers used in rotational molding, at Italveneta Didattica, we use linear low-density polyethylene (LLDPE). Other varieties of polyethylene, such as high-density linear polyethylene (HDPE), cross-linked polyethylene (XLPE), and PVC suspension (plastisol), are also used, sometimes in combination with other specialized polymers.

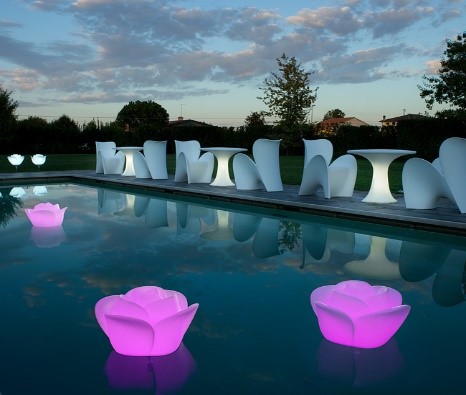

As mentioned, rotational molding is a technique that suits the luxury and designer furniture sector very well. We will soon see how MyYour, a company, has used this technique to create furniture that is true works of art.

Unlike other processing techniques, such as blow molding and injection, rotational molding provides optimal, refined, and high-quality finishing.

Another crucial feature of rotational molding is the ability to decide and vary the thickness of the plastic.

This unique capability is often utilized to create extremely robust installations where high performance for intensive use is required.

MyYour and Rotational Molding: Innovation in the Production of Furniture and Design Objects

Companies like MyYour are redefining traditional standards through innovation and the adoption of advanced production techniques in the design and furniture manufacturing sector. Choosing rotational molding ensures remarkable creativity, versatility, and durability of the finished products.

It allows the realization of shapes and structures that would be otherwise impossible to achieve with traditional methods, enabling the creation of complex and detailed designs with unprecedented design freedom.

Furthermore, as we have seen before, objects produced through rotational molding are known for their strength and durability.

This is particularly important in the furniture sector, where furniture is subjected to daily use and must withstand various environmental conditions.

MyYour demonstrates how the adoption of advanced technologies like rotational molding can lead to extraordinary results, creating an exciting and potential-rich future for this manufacturing technique.

Current Trends: Have you ever heard of "cracking art"?

It is an artistic movement that uses recycled plastic materials and rotational molding techniques to create visually impactful works.

This technique allows the creation of three-dimensional sculptures of considerable size and strength, ideal for public installations and outdoor environments.

Thanks to rotational molding, it is possible to create complex and detailed forms, while the versatility of plastic materials allows a wide range of colors and finishes, ensuring great creative freedom for artists.

Here are some examples: